Artificial Eye – Intelligent System

This project leverages computer vision techniques to automate quality inspection in production lines. It detects surface-level product defects such as cracks and scratches using image processing algorithms. Features include noise addition/removal, edge detection, and product counting—all accessible via an interactive graphical interface.

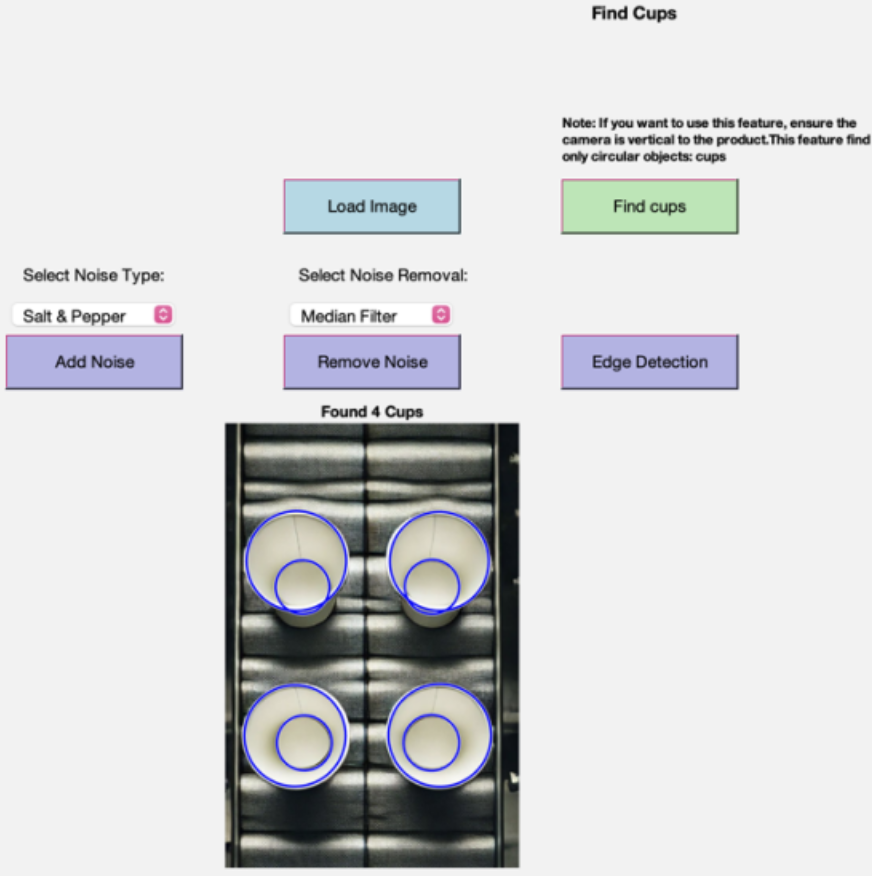

📸 Cup Counting Feature

The system identifies and counts circular items (e.g., cups) by analyzing shape and color features.

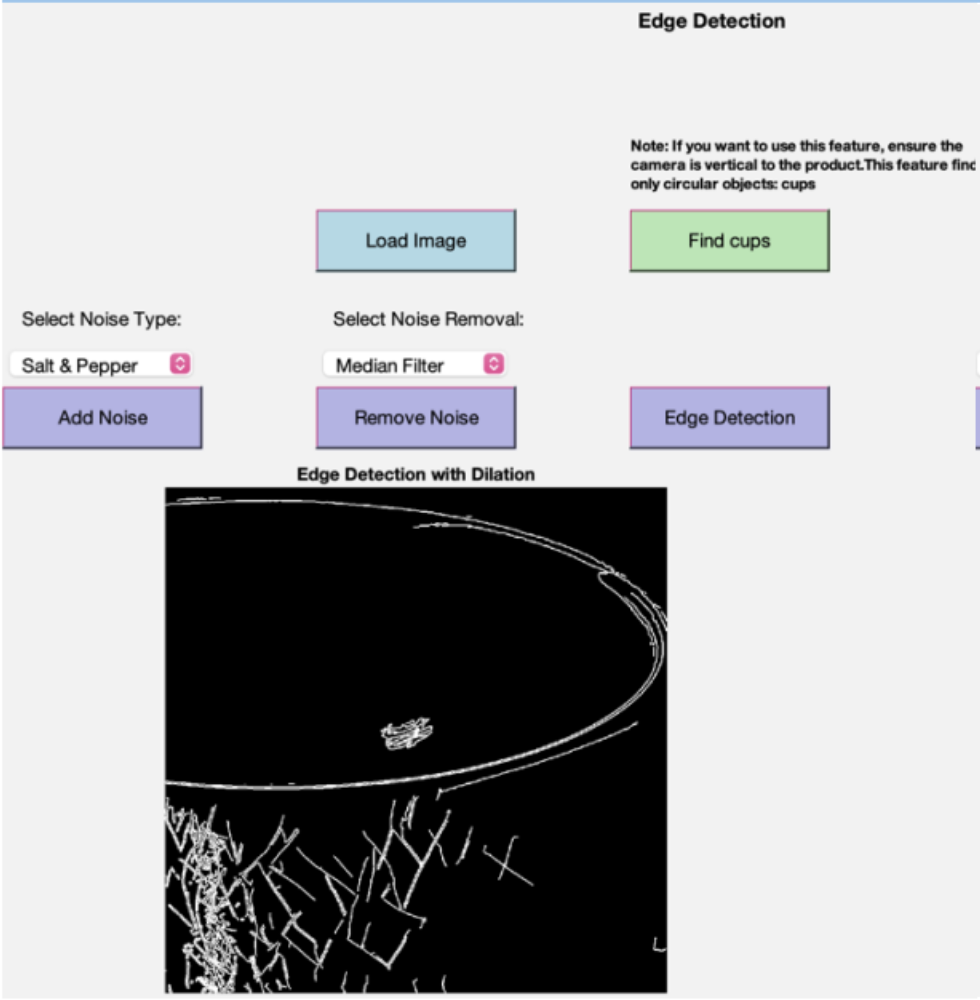

🕵️ Edge Detection Feature

Defect edges such as cracks are highlighted using Canny edge detection for better visibility during quality checks.